Volvo

Special Tool Designs

FAQ

Home

Volvo

Maintenance FAQ for 7xx/9xx/90 Cars

Version 5.0

Homemade Tools from Brick Owners

Homemade

Cooling System Pressure Tester. Here's what I've rigged up for both

pressure testing the cooling system and bleeding the clutch and brakes:

I found an old bottle cap that has the same threads as the coolant reservoir.

Then I bought $1.00 worth of tank valves and screwed one into it. If you

don't have such a cap, then an old coolant reservoir cap should work even

better. When I need to use it, I take the gasket out of the coolant reservoir

cap and use it in my "pressure cap". I connect a $5.00 bicycle pump (with

built in pressure gauge) to the cap and presto. Since the brake reservoir

has the same type orifice, it can also be used to pressure bleed the clutch

and brakes.

Fuel

Pressure Test Tool. At last check, Volvo wanted $600 for the pressure

rig to test control,

system, and residual pressures. I built

one for much less ... here's how. Parts needed:

2 Banjo 'nut' fittings (the ones that

actually look like a banjo). Hack apart old fuel lines from an Audi, VW,

or BMW from the wreckers to get the ones with the small nipples. Make sure

they're the same diameter as your Volvo (see the tip below for Volvo

parts needed.)

1 Brass Tee , 3/8" NPT

1 Brass Valve, 3/8" NPT=20

1 150 psi gauge

2 2.5" 3/8" NPT brass extender (pipe w/

both ends threaded)

2 3/8" NPT brass nipples

2" vacuum hose

4 small tie wraps (zip ties)

1 nylon spacer, 2" long, that will accept

the 'bored' banjo bolts

some telfon tape for sealing

Now, hook them up in this order:

Banjo Nut - 1" vacuum hose - nipple - extender

-tee -valve -extender-nipple-1" vacuum hose - Banjo Nut

Use the tie wraps to clamp the vacuum hose

onto the banjo nuts and the nipples. Vacuum host isn't ideal for this,

but the tests are short term and a short piece of the hose holds the pressure

just fine. The gauge goes on the top of the tee. Be sure to use teflon

tape to seal all connections.

One of the banjo bolt goes where your control

pressure feed line connects to the fuel distributor. The other one gets

bolted into one end of the nylon spacer. The other end of the spacer has

the control pressure feed line bolted to it.

Now, follow your Bentley or Haynes directions

to test... when placing the tester into the fuel circuit, be sure to orient

the valve on the correct 'side' or else you'll only be able to measure

system pressure.

Special Volvo Fittings to Make Connection.

[Tip

from Neal] Here are the Volvo part numbers for two hard to get parts needed

to build a fuel pressure gauge assembly:

9995267-7 Nipple $27.45

9995116-2 Hose $ 9.30

The nipple is the fitting that connects

between the rubber fuel line and the fuel rail. The hose includes the banjo

fitting that attaches inline with the nipple. The other end of the hose

is an unusual fitting that I imagine could connect only to a Volvo fuel

pressure gauge. I cut that fitting off, and installed a 1/8" male pipe

thread with barbed fitting pressed onto the hose. The 1/8" male pipe screws

into almost any fuel pressure gauge found at any auto store. Make sure

you get a gauge that goes to at least 100psi.

B230F

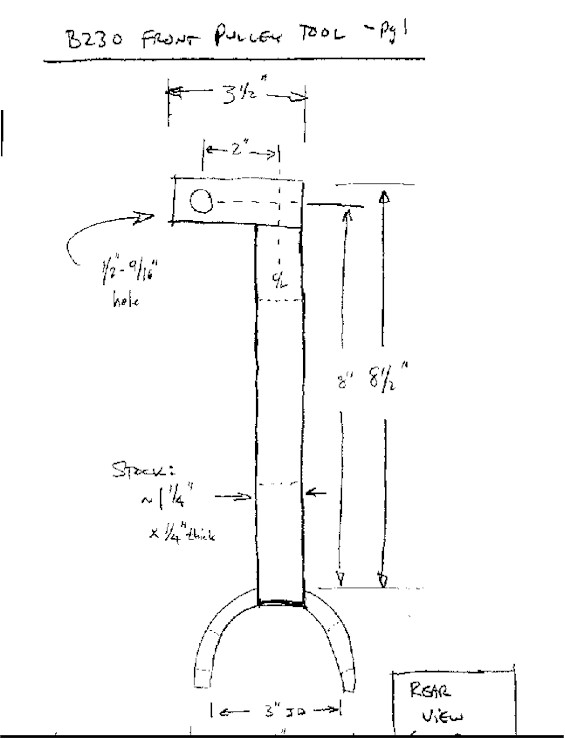

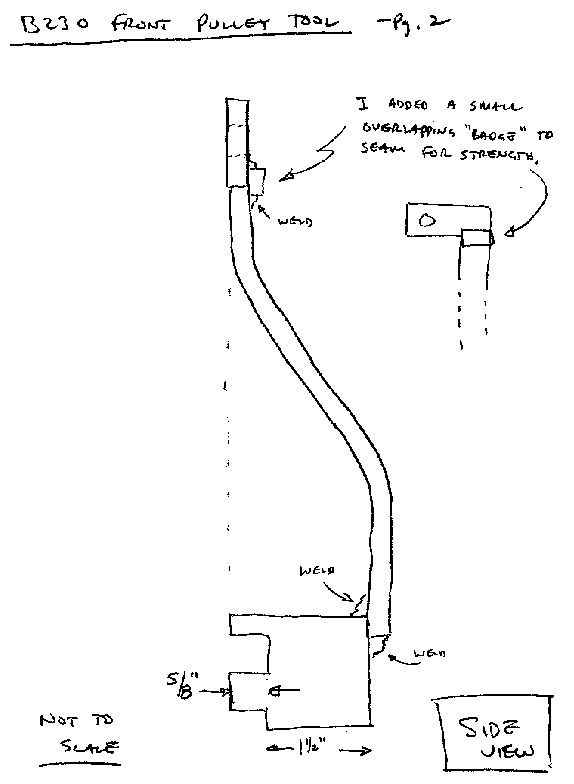

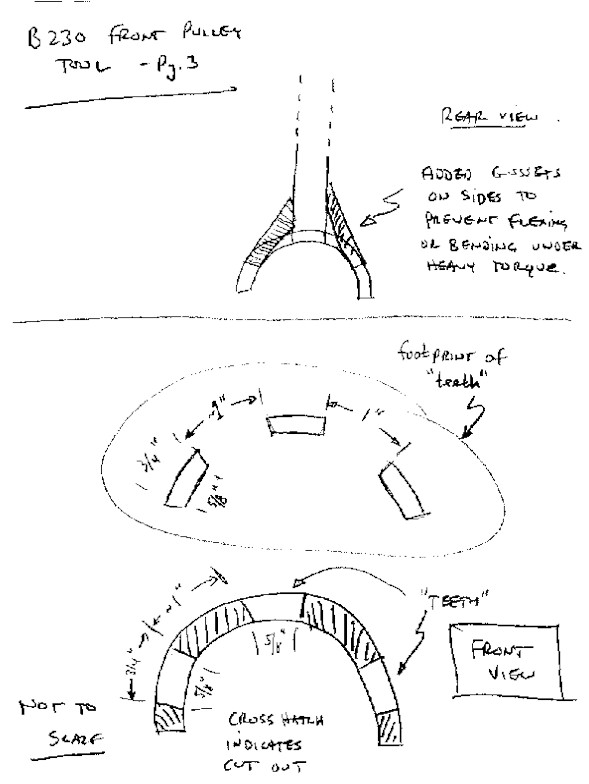

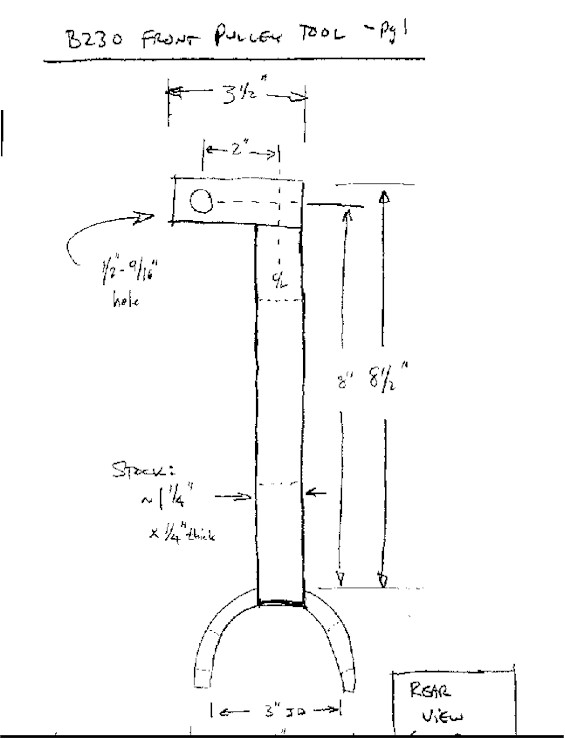

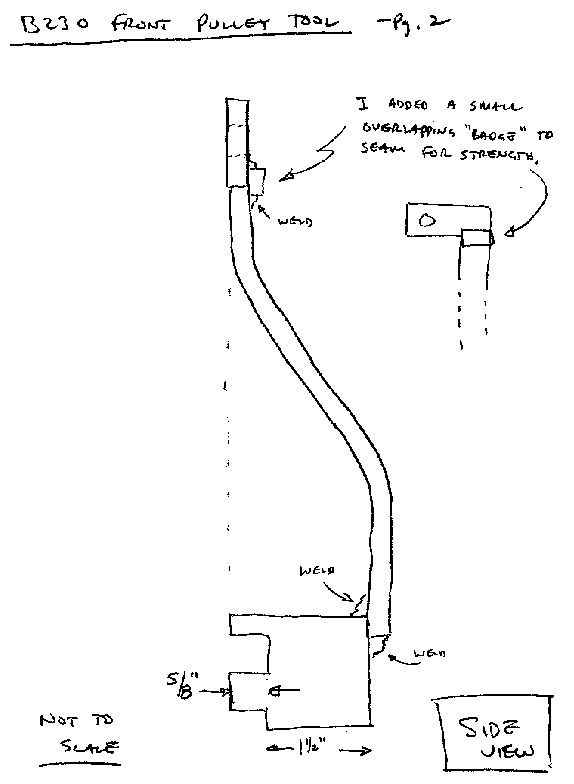

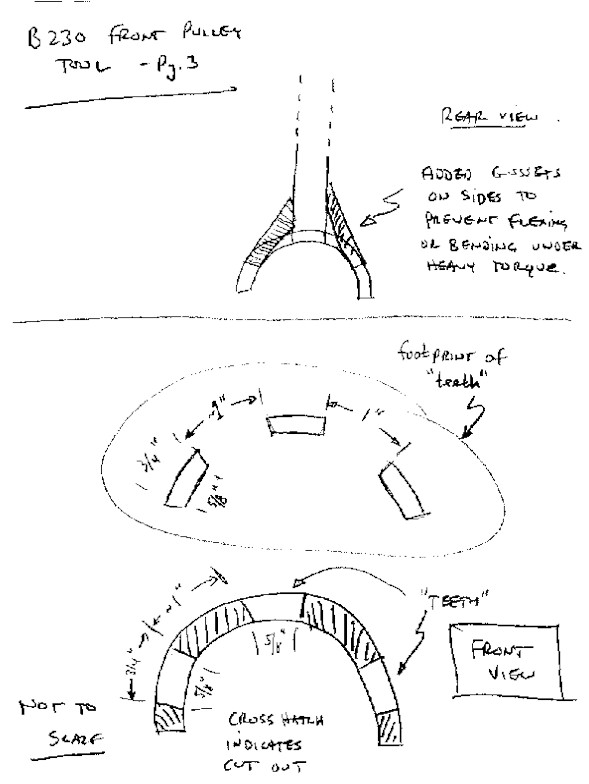

Crank Holder Tool. [Don Foster] Here is the design for

the tool used to secure the crank pulley to remove the bolt while changing

the timing belt. [Editor's Note: You can purchase this tool number

5284 from Volvo dealers; see the FAQ section on Timing

Belt Tips]

Rear View:

Side View:

Detail of Rear and Front Views:

Vacuum

Leak Checker. [Tip from Paul Kane] A good vacuum leak check device

is a butane charcoal lighter. Don't light it, just use it for

'sniffing' around the suspected leak. Apply the butane to the potential

leak- if RPMs change - you've found the leak.

Large

Gauge Wire Crimper. [Tip from Tom Harper] Ever needed to

get a solidly crimped electrical terminal on larger cables (8 - 4 gauge),

but found the cost of crimp tools in that size to cause "sticker shock"?

Here's something I've been doing - it works for UNinsulated terminals.

1. Measure the OD of the uninsulated terminal

barrel you need to crimp

2. Find (or buy - a dime or so) a nut

with a thread size (thread OD - not ID) equal to or slightly smaller than

the size in step 1

3. Drill out the nut to match the terminal

OD

4. Cut the nut in half, across opposing

corners (NOT across the flats). Your Dremel tool will come in handy for

this - a hacksaw will do it also, just takes more time.

5. Find a piece of round stock about 1/8"

- 3/16" (3-4 mm) diameter, about 3/8" (1 cm) long (you can cut the head

off a screw for this - the threads won't affect anything.)

You now have a "saddle" and a "punch" (halved nut & screw/round stock

piece).

6. Put the terminal in the "saddle", and

the "punch" lying lengthwise on top of the terminal, opposite the "saddle"

- you'll probably want to tape the assembly together, otherwise it takes

3 or 4 hands.

7. Put the cable end into the terminal,

and crimp the whole works together using a bench vise, Vise-Grips, or equivalent.

The "saddle" supports the bottom of the terminal, while the "punch" crimps

everything nice & tight.

I've gotten really tight & secure crimps

on up to 4 gauge cable by hand with this method. After a dozen or so uses,

the nut may crack & start to spread; no problem, since you have the

other half, and making new "saddles" is easy & cheap anyway.

Make sure your terminal barrel ID is close

to the wire OD - this method doesn't do too well if there's a lot of empty

space between the wire and the terminal. You may be a bit clumsy at first,

but once you work out a way to keep everything aligned as you start the

crimp, it'll go really well. The new Vice-Grip adjustable wrench

is ideal for this - the "V"-shaped jaw is ideal for supporting the "saddle".

Volvo content - used this trick yesterday

when making some "overkill" (4 gauge) engine-to-body ground and alternator-to-starter

terminal cables.

M-46

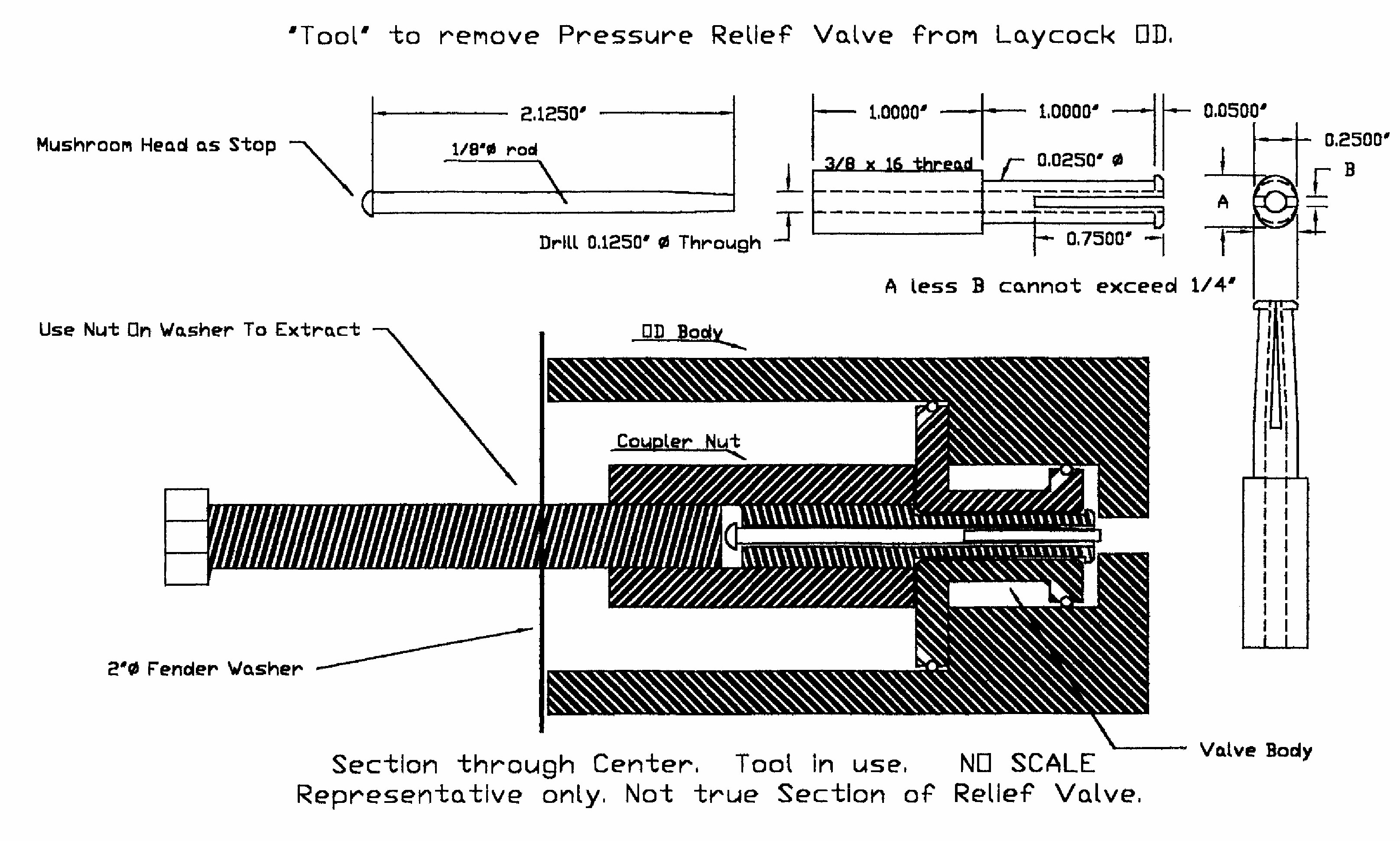

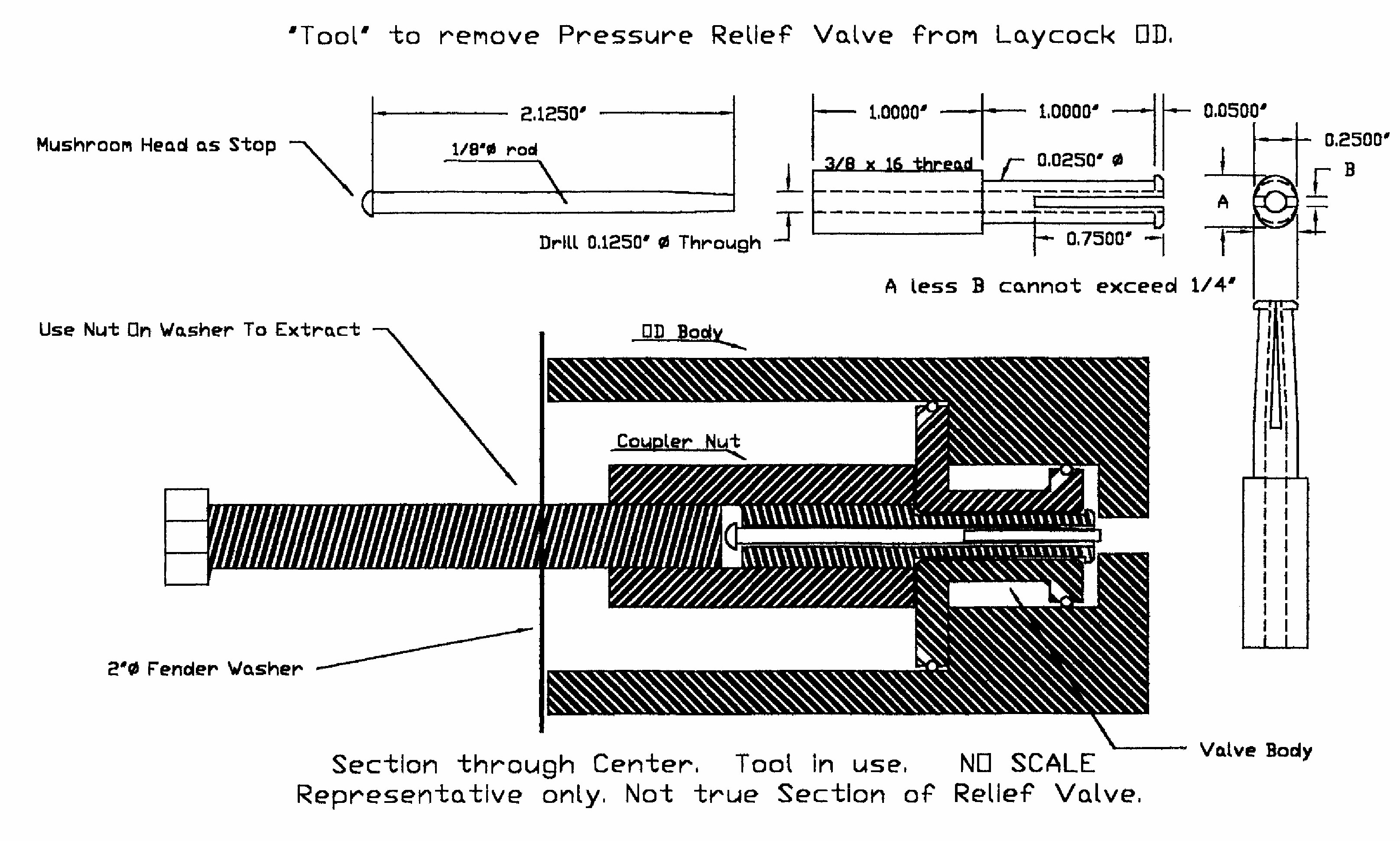

Overdrive Pressure Relief Valve Tool. [Duane Hoberg] Here

is a tool I designed for removing the Pressure Relief Valve ( between numbers

22 and 23 on the diagram

of the overdrive

overhaul procedures.

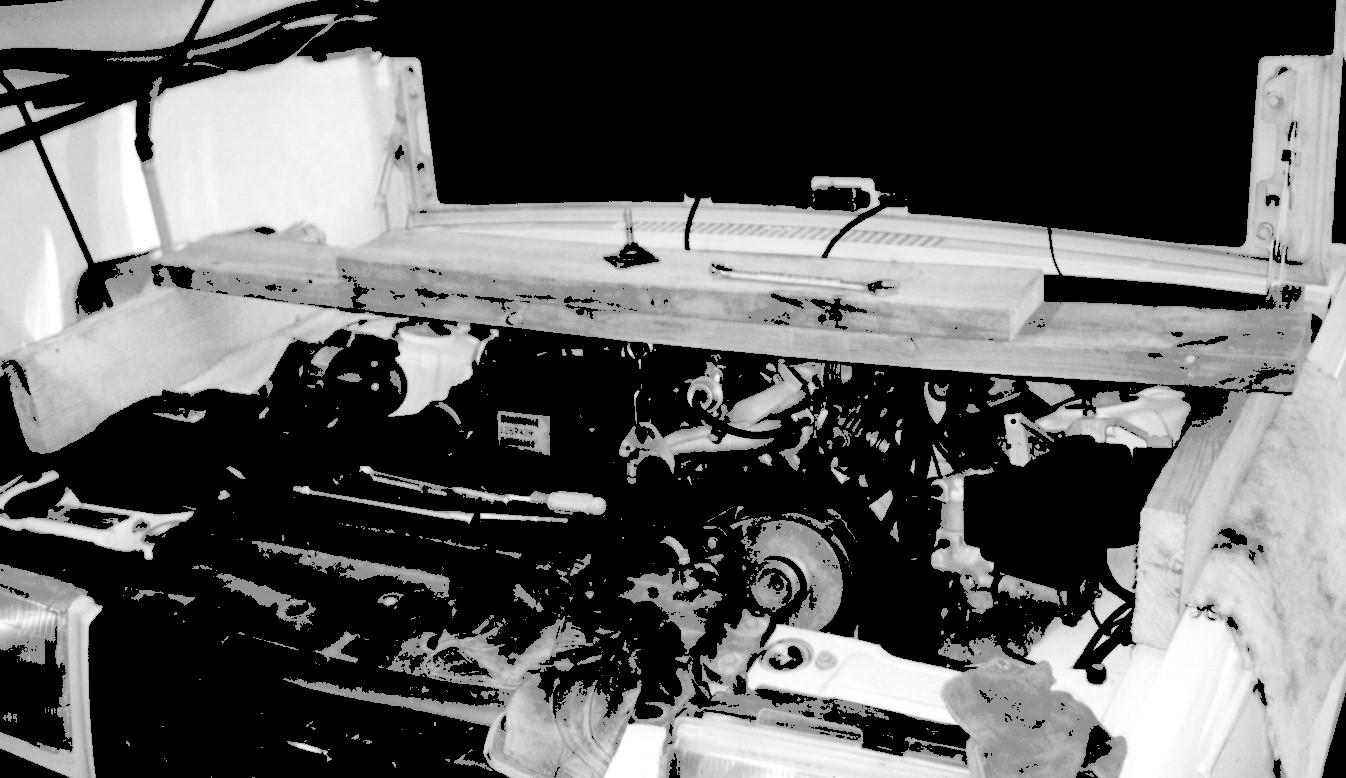

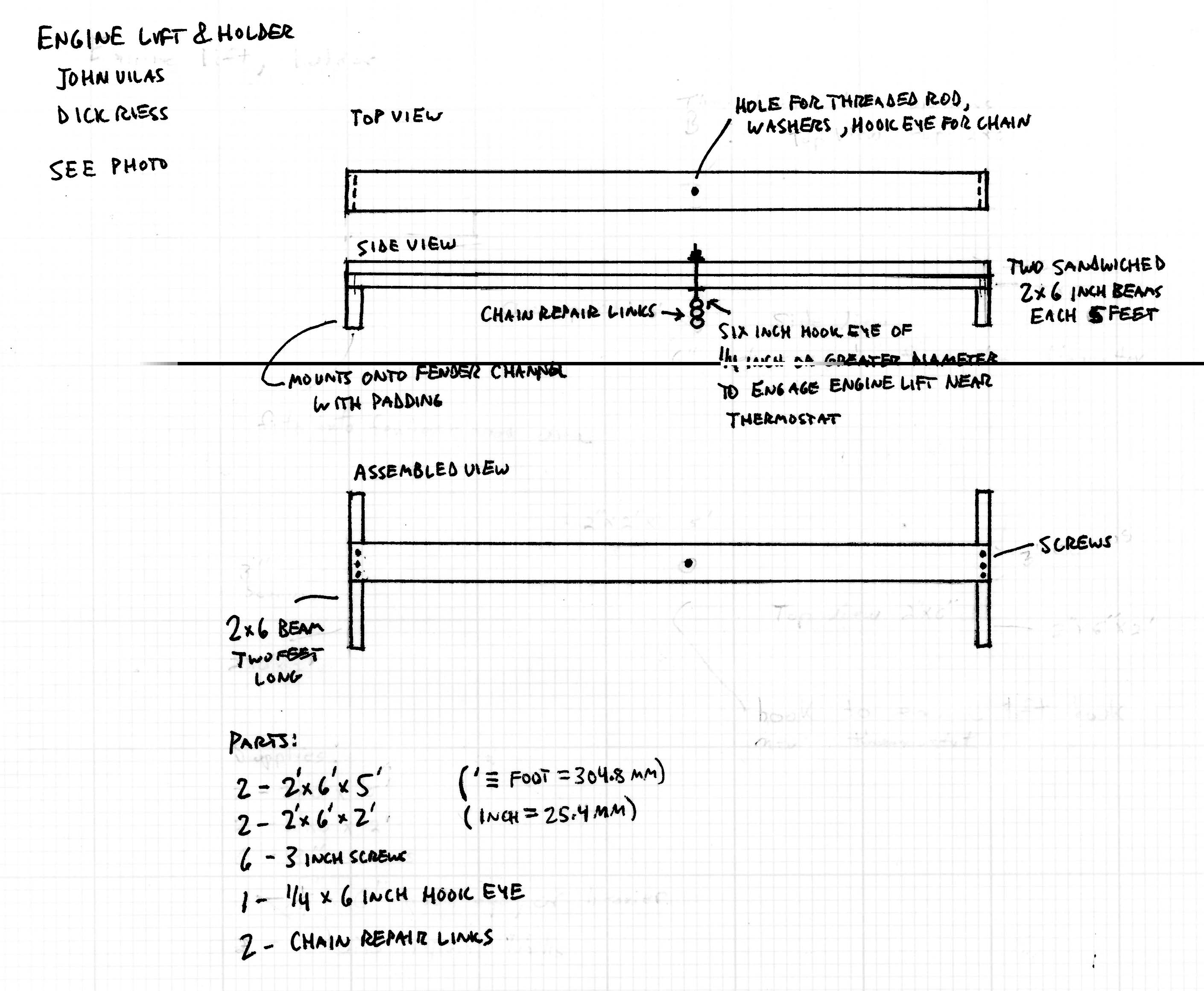

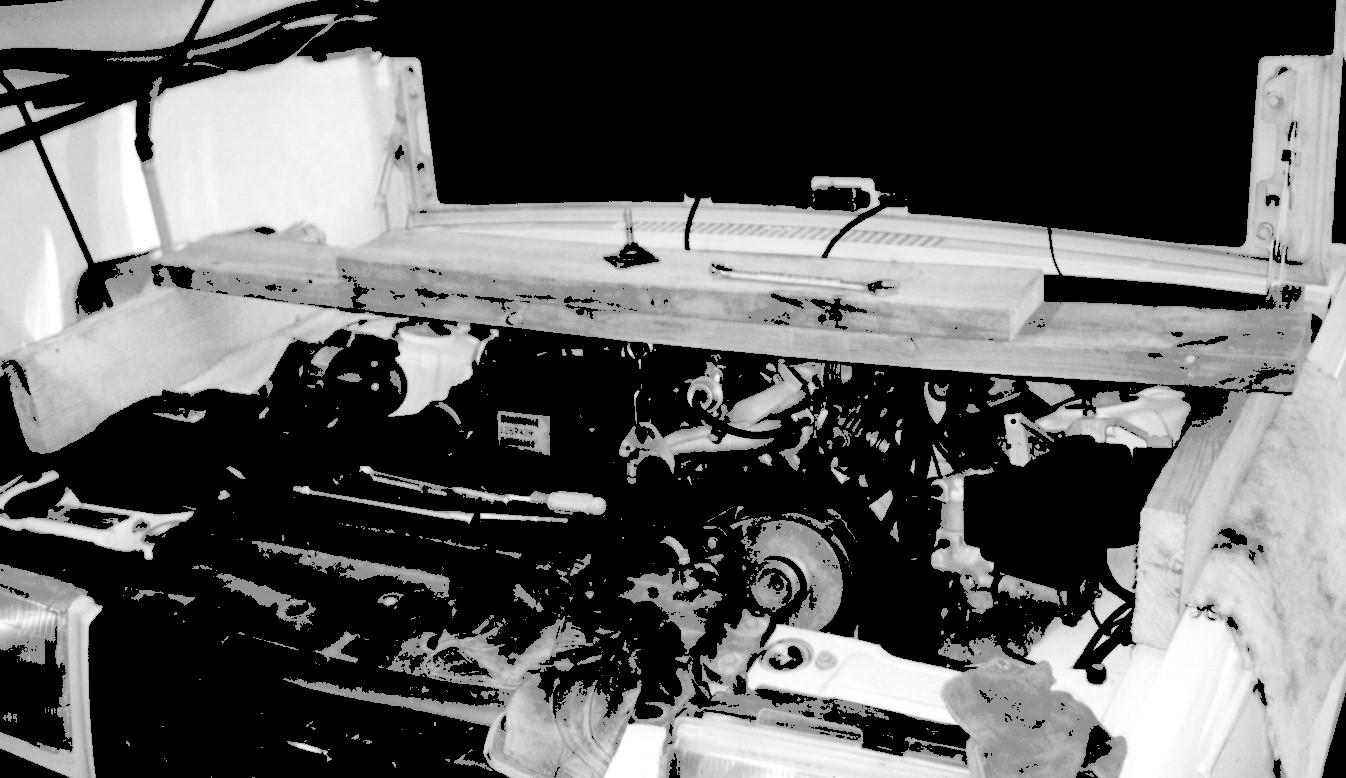

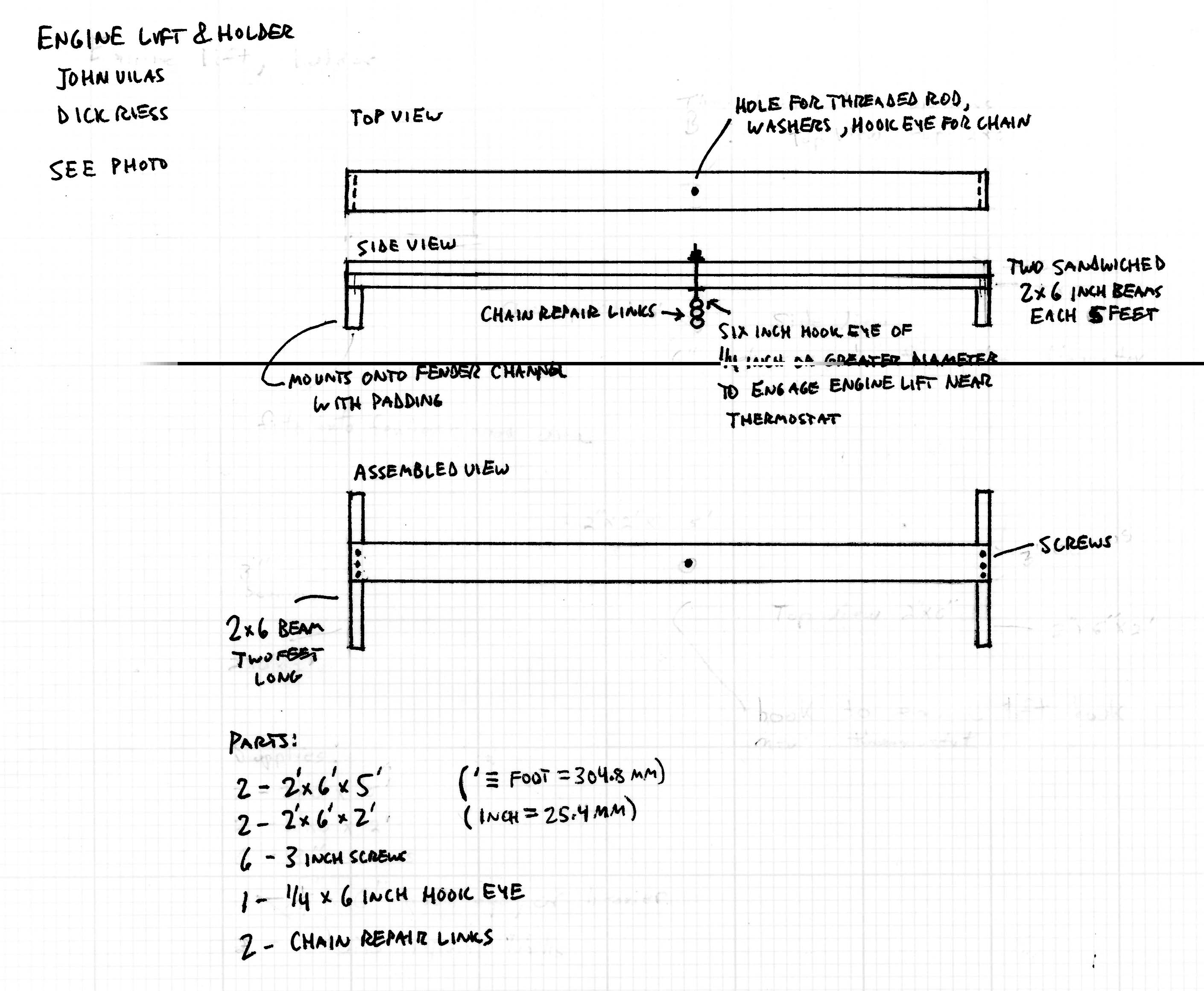

Engine

Lift and Support. See the photo and planform for Dick Riess'

and John Vilas' design for an engine lift and support, useful for changing

motor mounts and oil pans. It is made of 2x6 lumber and mounts on

the fender channels.

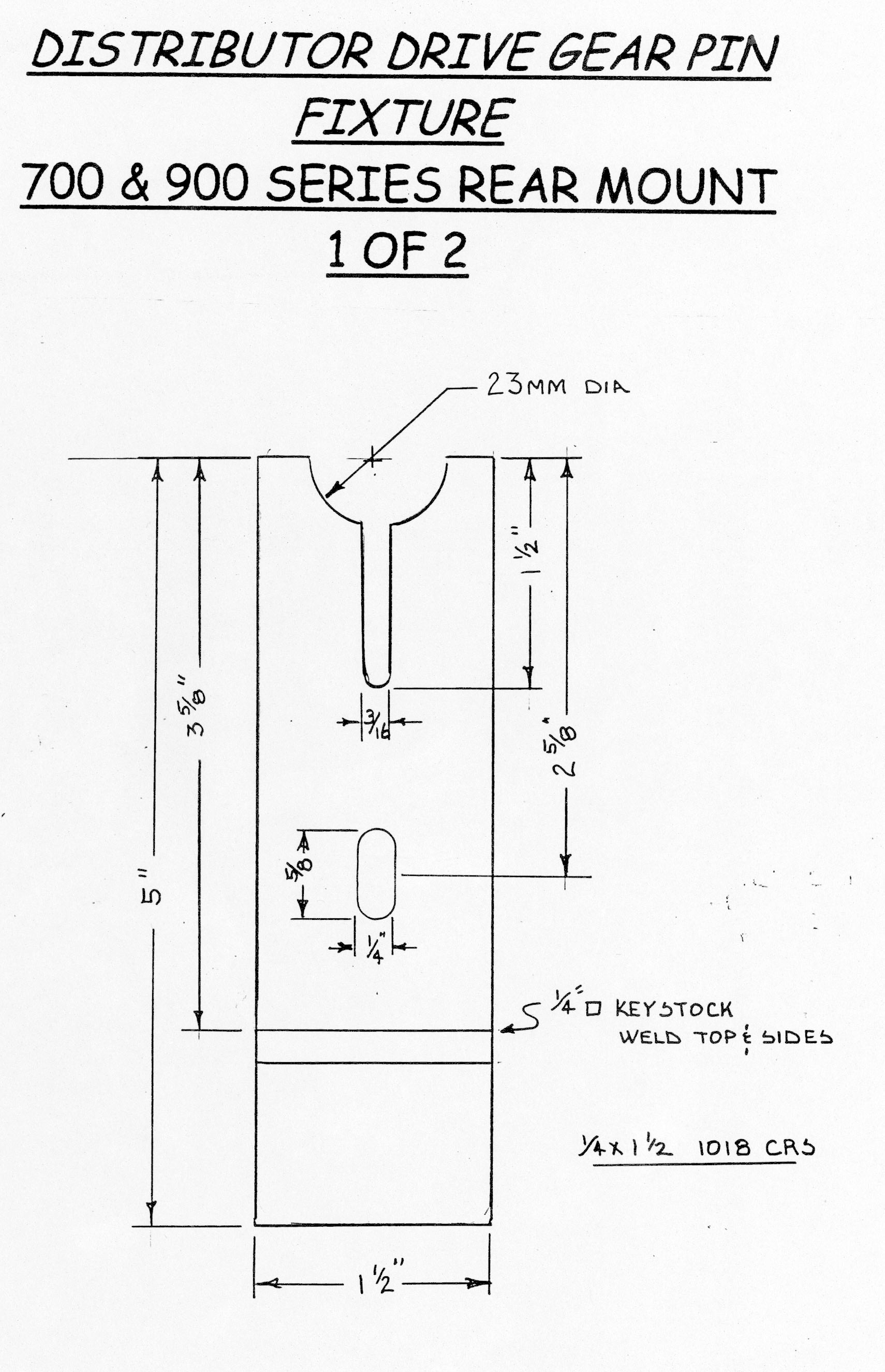

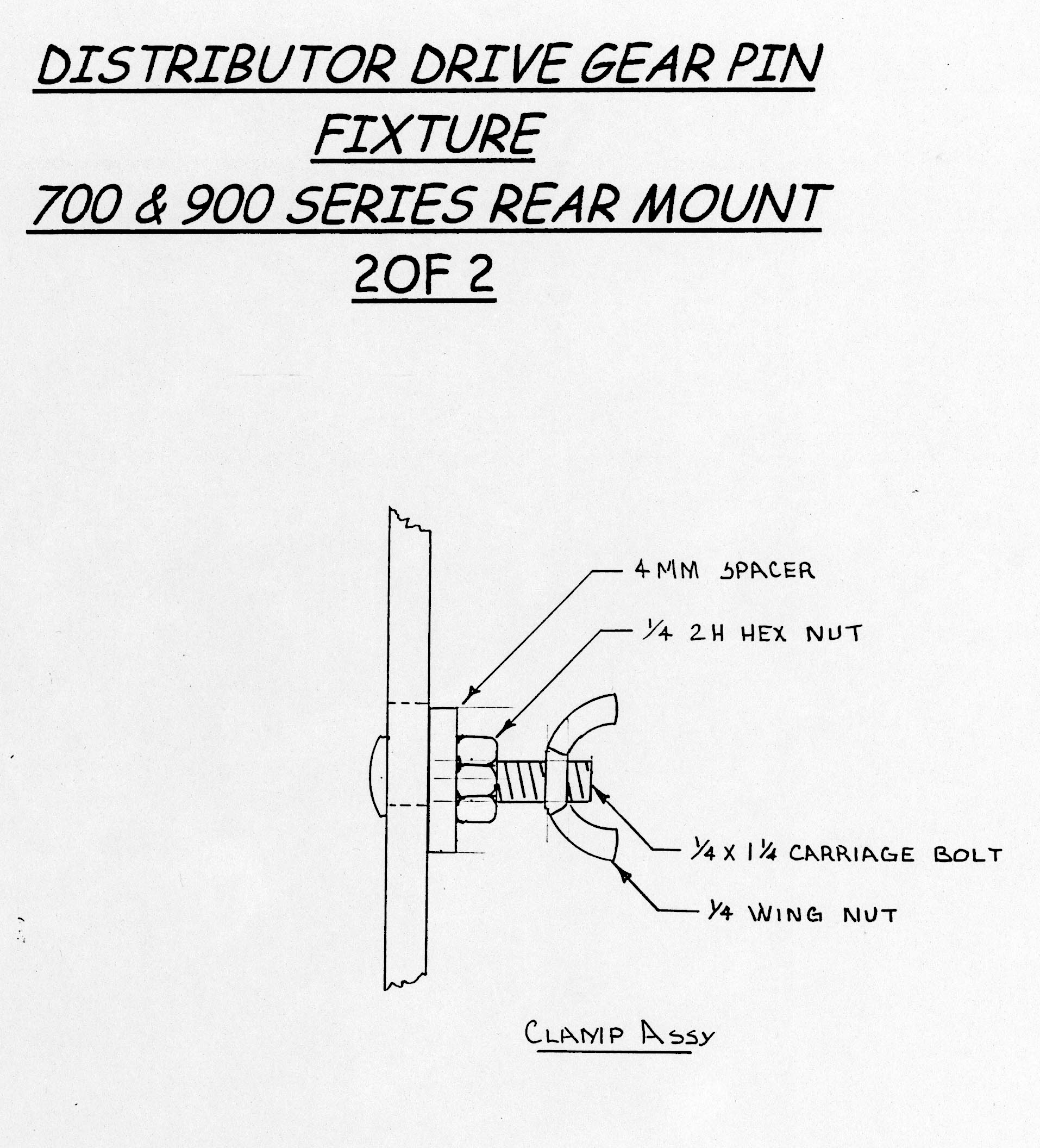

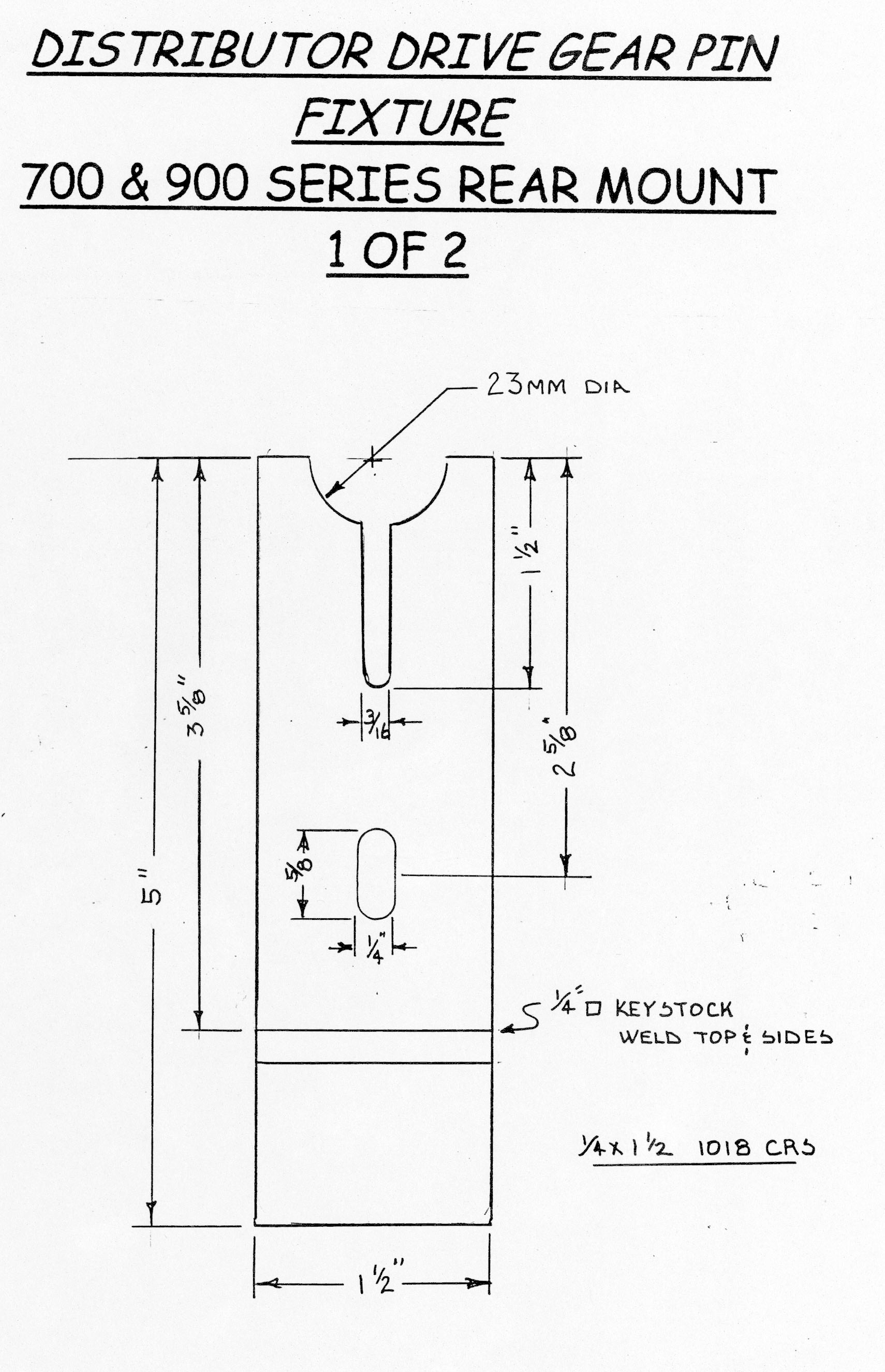

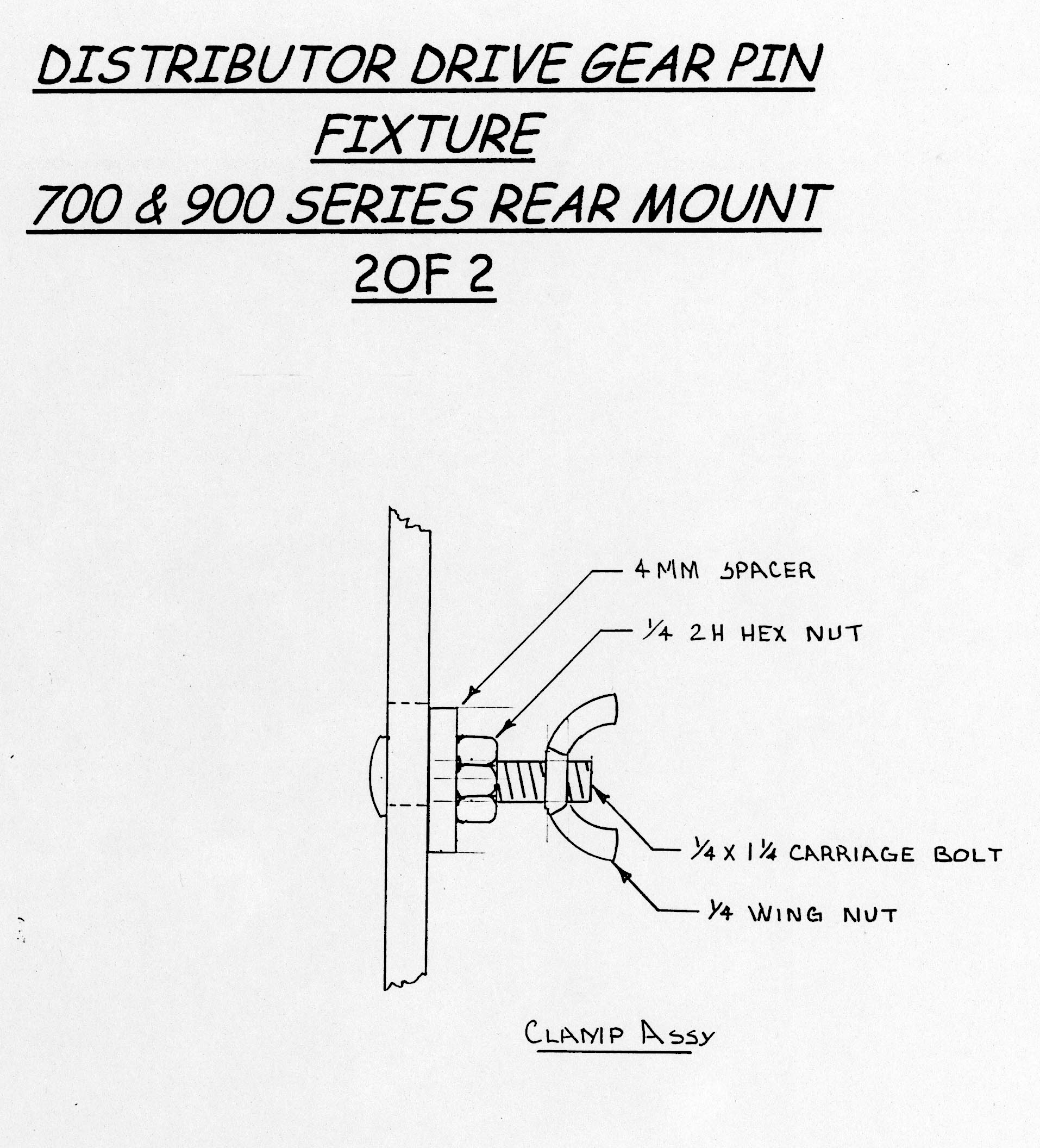

Distributor

Drive Pin Remover Tool. [Tool design by John Vilas] This

tool may be used with a vise or hammer to remove the shaft pin holding

the distributor together. You will need it should you ever decide

to change the inner o-ring seal on this shaft. You can purchase this

from:

John Vilas

Vilas Motor Works

901 S. Texas Avenue

Bryan, TX 77803-4554

Cost is $25 (at 6/6/00)

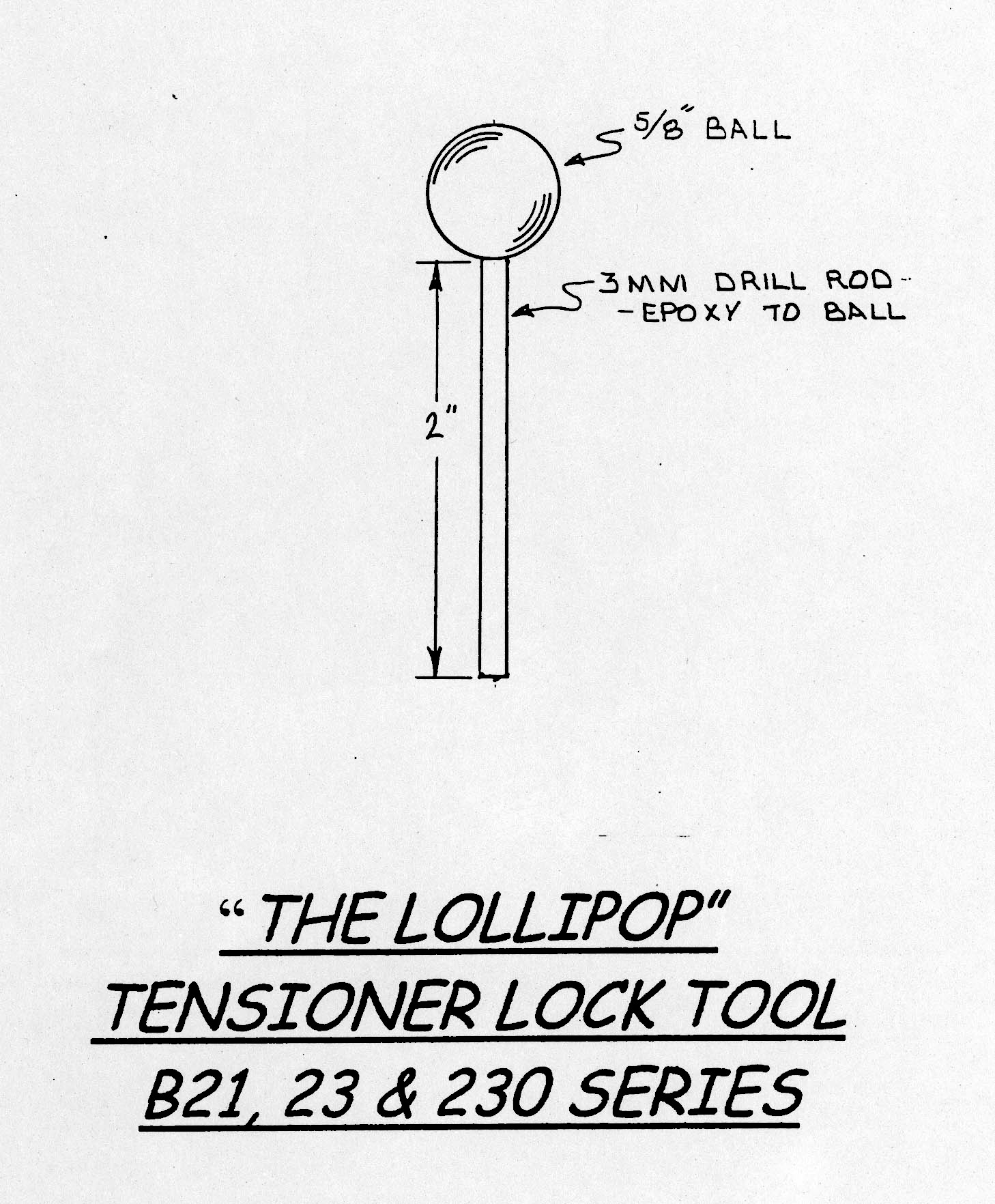

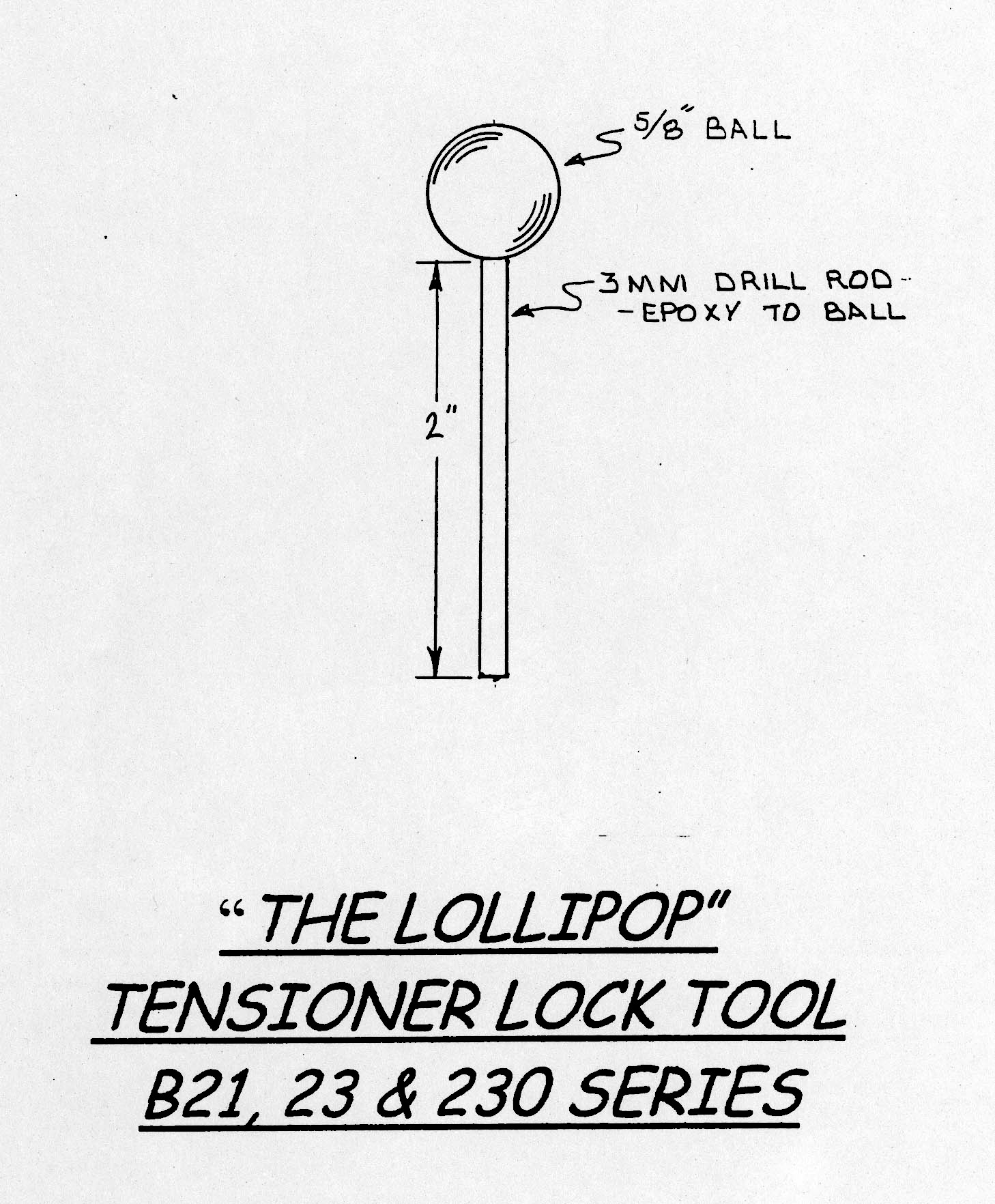

Timing

Belt Tensioner Lock Tool. Use this to secure your tensioner pulley

out of the way when installing a timing belt in B21/23/230 engines.

Purchase it from:

John Vilas

Vilas Motor Works

901 S. Texas Avenue

Bryan, TX 77803-4554

Cost is $12.50 (at 6/6/00)

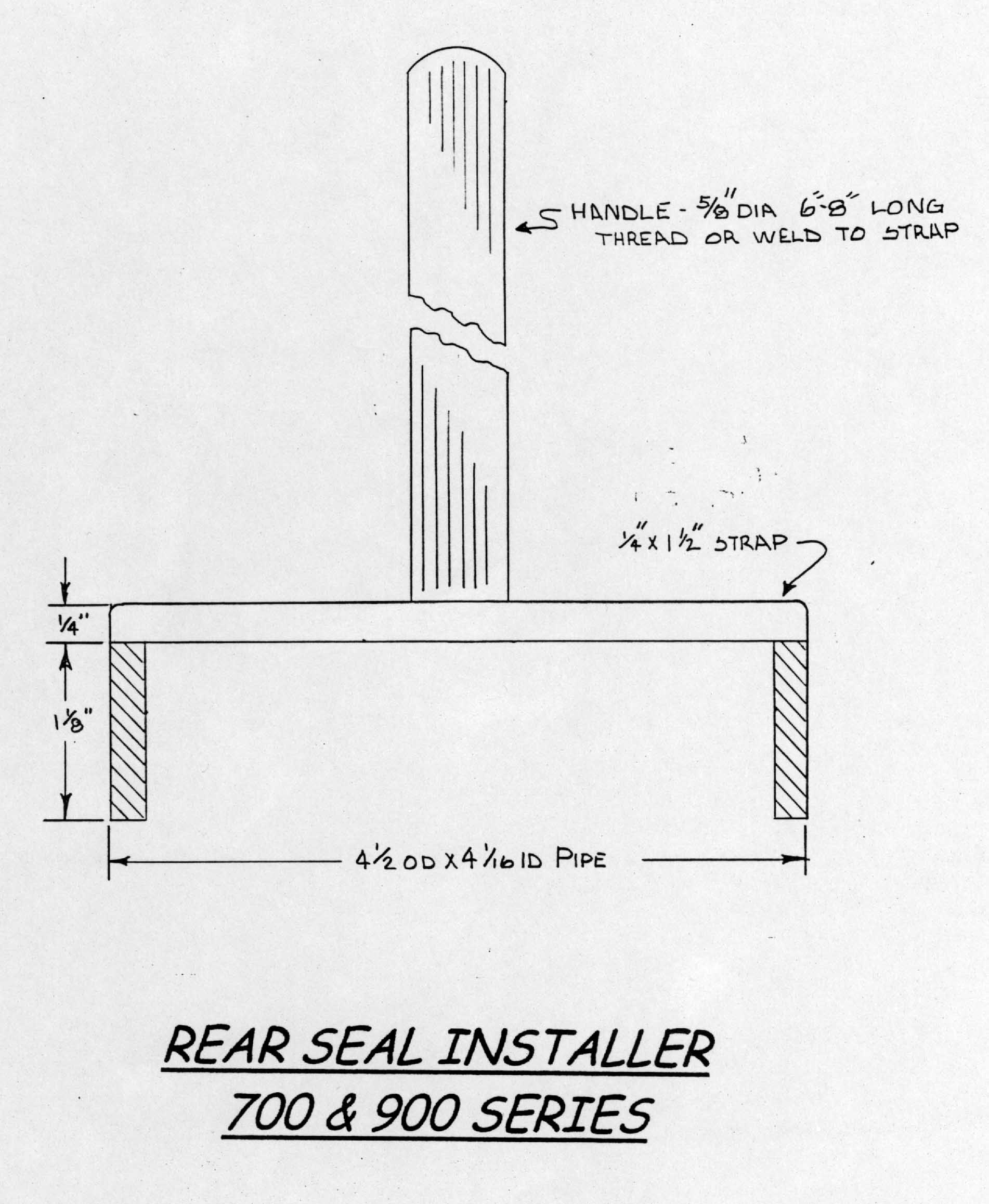

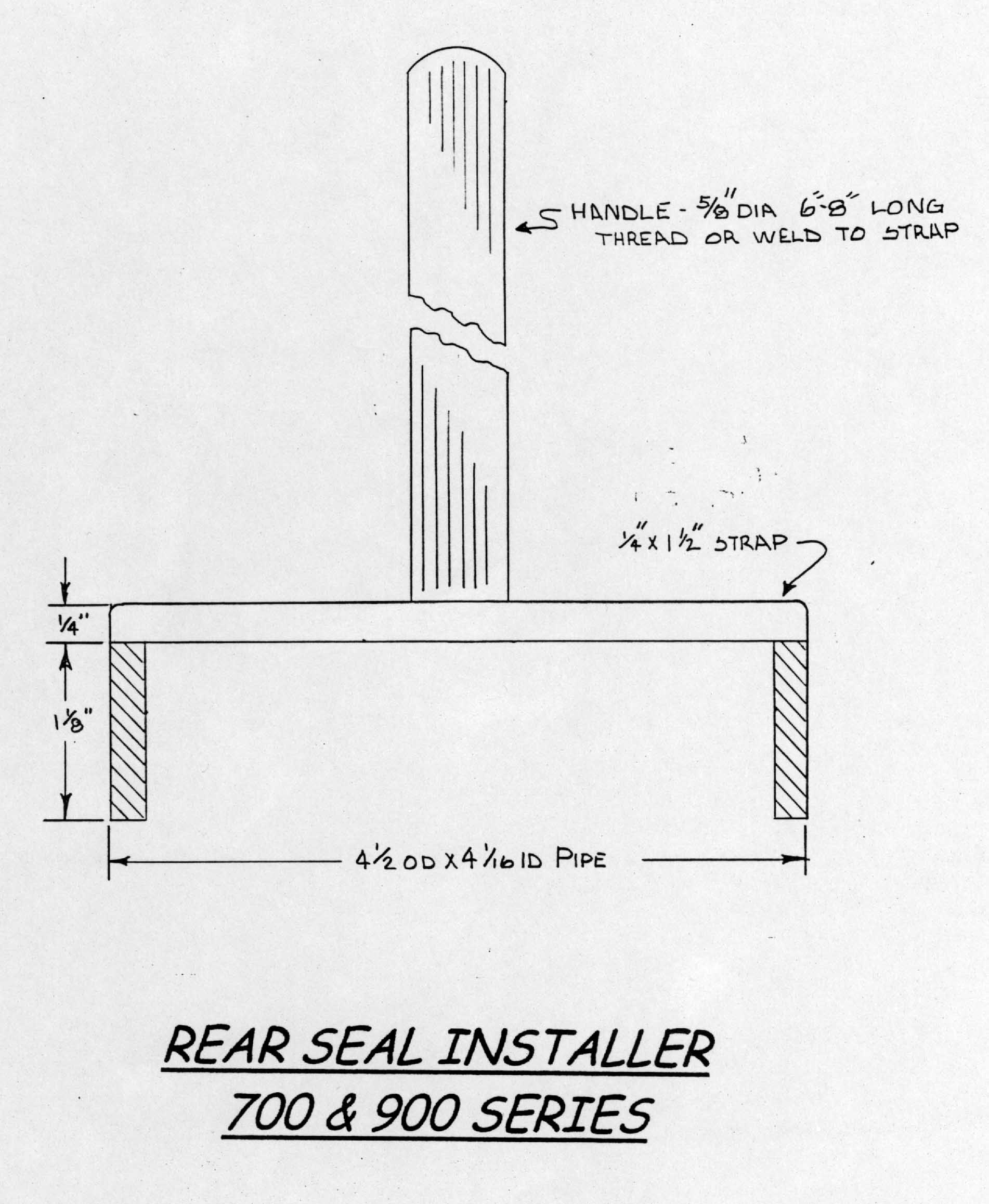

Rear

Engine Seal Installer Press. Use this press to correctly install

your engine rear main seal on B21/23/230 series engines. Purchase

it from:

John Vilas

Vilas Motor Works

901 S. Texas Avenue

Bryan, TX 77803-4554

Cost is $35.00 (at 6/6/00)

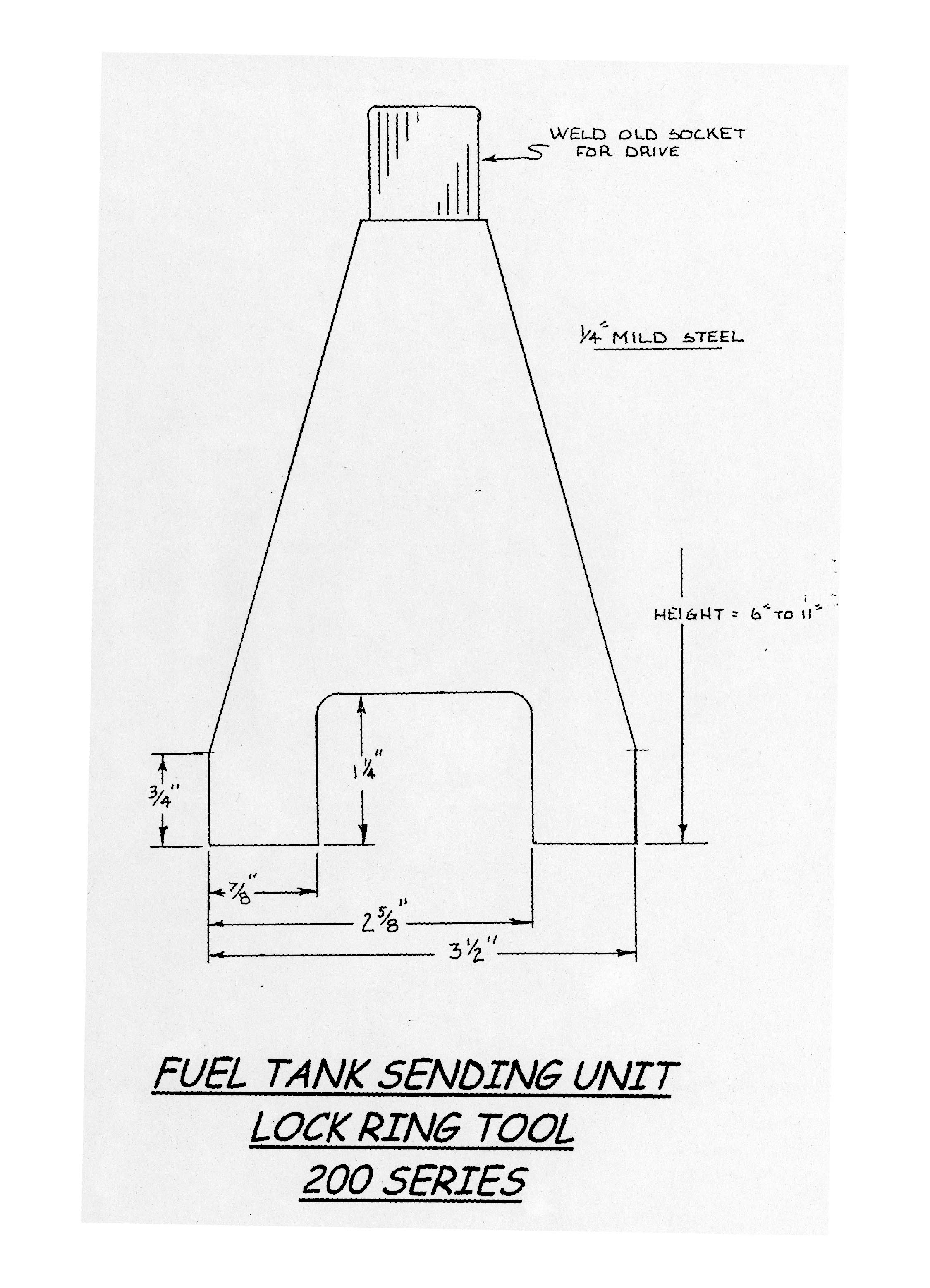

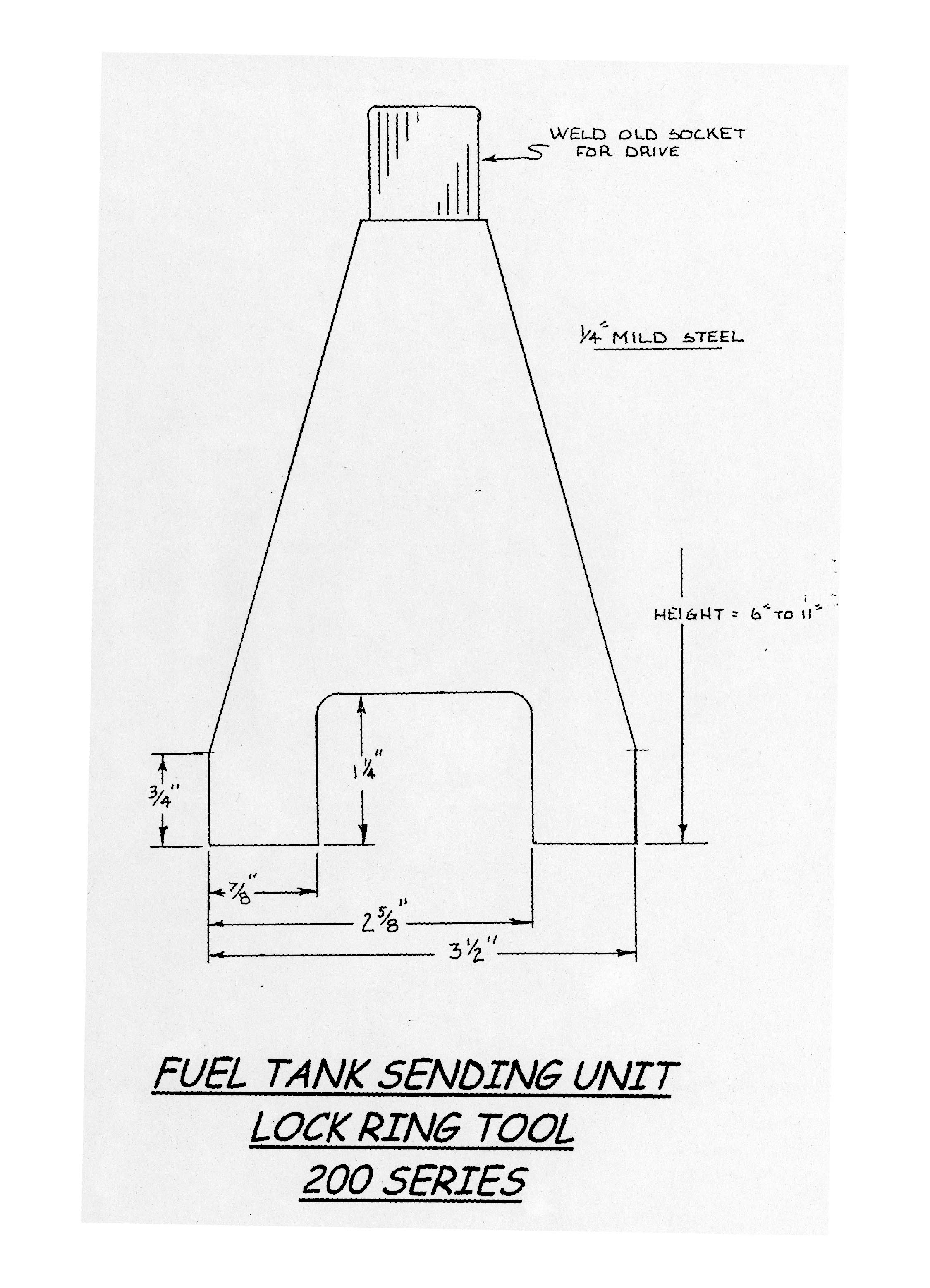

Pre-Pump

and Fuel Tank Sending Unit Removal Tools. [Special bonus for

200-series owners!] Use this lcok ring remover to take out your sending

unit on 200-series cars. Purchase it from:

John Vilas

Vilas Motor Works

901 S. Texas Avenue

Bryan, TX 77803-4554

Cost is $25.00 (at 6/6/00)

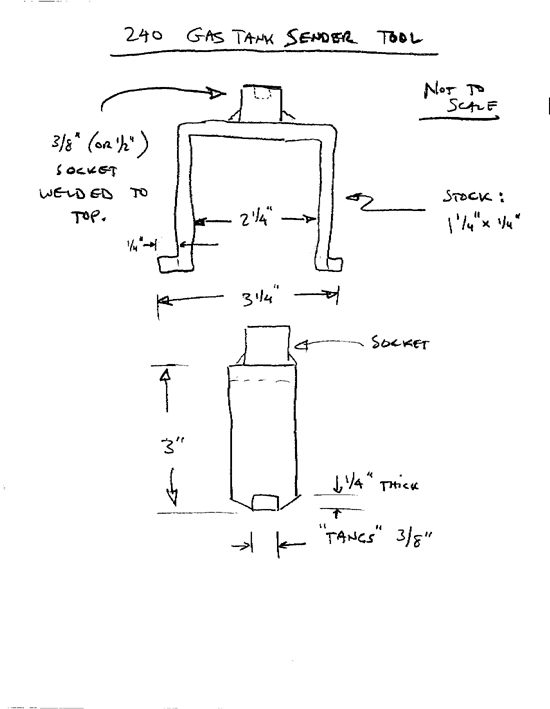

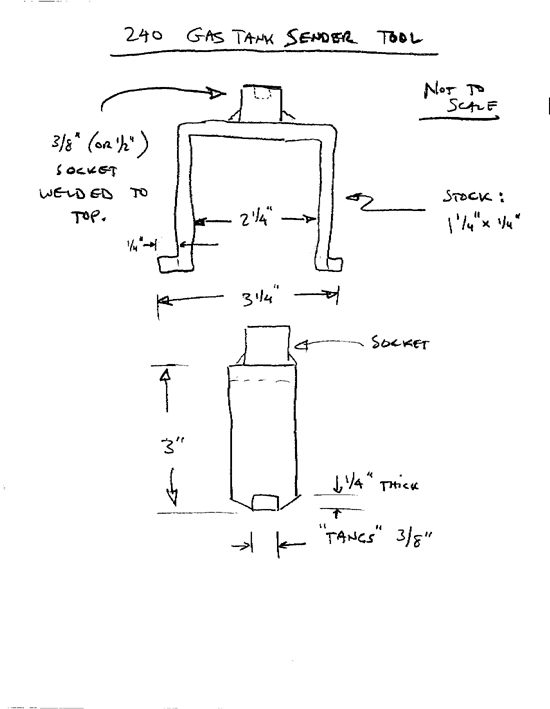

Pre-Pump Removal Tool. [Tip

from Ross Gunn] Anyone have a Prepump tool they used when they removed

the pump from the tank? Volvo has one of these tools, anyone have

one they wouldn't mind loaning out? I'm afraid of taking screwdrivers to

it as I might break something. Any ideas?

I made one out of 1/8"steel plate which

I shaped like this:

__________^____________

|

|

| _______________ |

|__|

|__|

Using vice grips as a handle at ^ , it

was quite easy to remove the level sender/pump unit.

Another version for 240 cars by Don Foster:

Volvo

Maintenance FAQ for 7xx/9xx/90 Cars

Top of Page